Kesht va Sanat Shomal Complex

Kesht va Sanat Shomal Co. [Shomal Agroindustry Co.] started out in March 1975 with a nominal capacity of 100 tons per day. In 1977, the factory relocated and now is spanning an area of about 32 hectares on account of ongoing development projects. Following its privatization in 1993, the production capacity was increased by upgrading equipment in stages. The factory was transferred to Modallal Group in 2005, and the production capacity was gradually increased thanks to an equipment development plan, eventually reaching 1,200 tons per day.

1353

Establishment

553

Personnel

34

Product

5

Brand

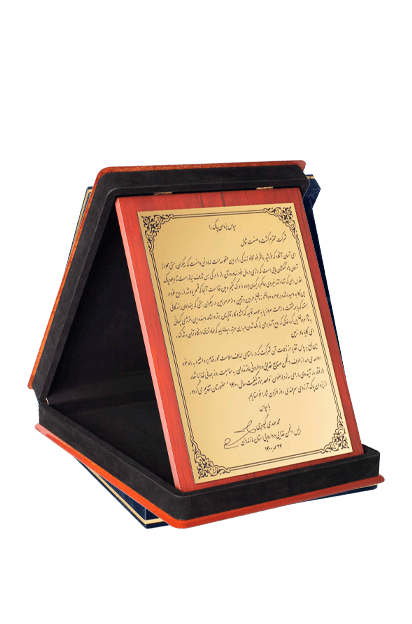

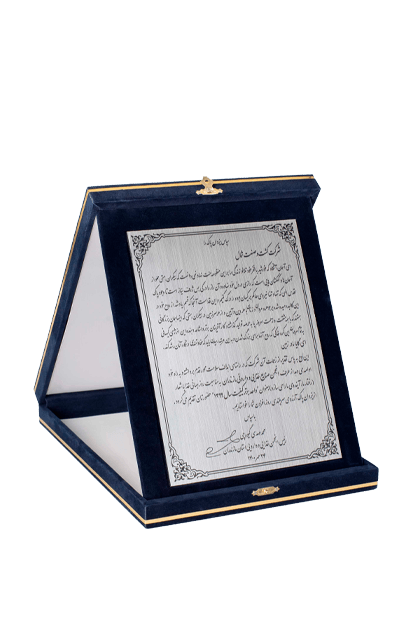

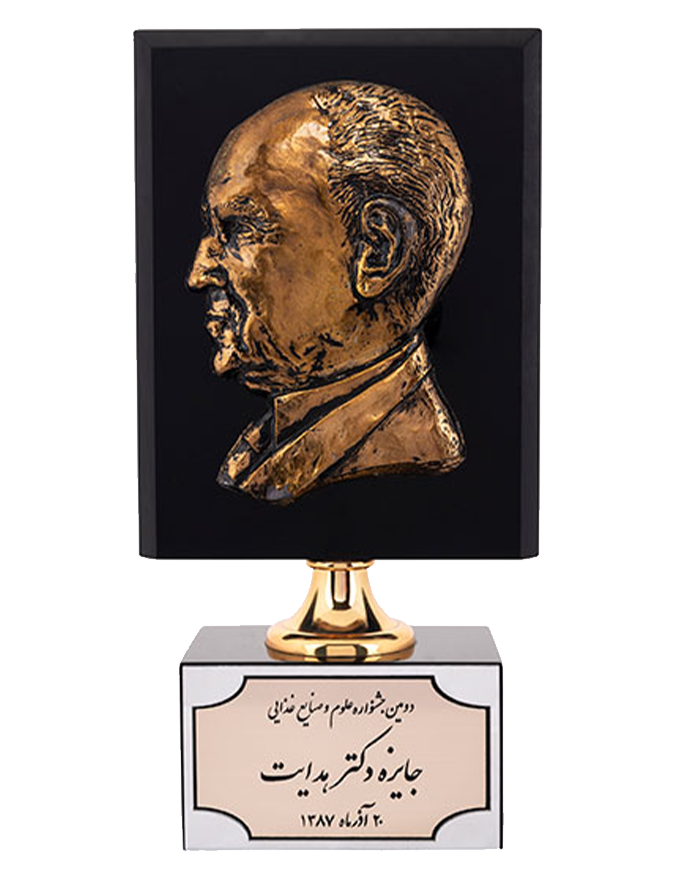

Honors and Awards

Previous

Next

Processes

Crude oil input into factory

Transfer to oil refinery unit

Transfer to filling halls

Transfer to packaging unit

The factory's output

Crude oil input into factory

The crude oil enters the factory via wagons, which follow the railway line inside the complex, or via crude oil transport trailers, and is then transferred to crude oil storage reservoirs based on the type of oil

Transfer to oil refinery unit

The crude oil, which includes palm, sunflower, soy, corn, olive, and rapeseed oils, is fed into the refinery unit. First, gums and phosphatides are separated from oil in the neutralization unit, and free fatty acid is reduced. The oil then enters the bleacher in the following stage (primary bleaching). After total soap removal, reduction of carotenoid and chlorophyll pigments, and removal of heavy metals, oils enter bleach storage tanks in this unit.

Transfer to filling halls

The oil stored in the hydrogenation unit's tanks is fed to the ghee unit, which produces ghee for confectionaries and margarine, and the blending unit, which produces special odorless oils for liquid oils, or the winterize unit, which dewaxes the oil. After being fed to deodorizers and losing flavor and free fatty acids and dyes to a standard level, the winterized hydrogenized oil or liquid oil enters reservoirs to be offered to customers

Transfer to packaging unit

After being sent to reservoirs, the oil from the refinery unit (the output of the deodorizer) is distributed to customers in four different ways: metal packages, PET bottles, carton packages, and bulk loads.

The factory's output

1. PET bottle packaging and marketing: Oil bottles are transported to the warehouse via conveyor belts after leaving the filler halls, labeling, and packaging, and are then presented to customers; 2. Carton packaging: This group of products is filled into foils and cartons after adding the required additives, and then transferred to cold storage for storage and quarantine before being presented to customers; 3. Bulk loading: After being transferred to bulk oil reservoirs, bulk oils are loaded onto steel oil tankers by refinery personnel for delivery to customers